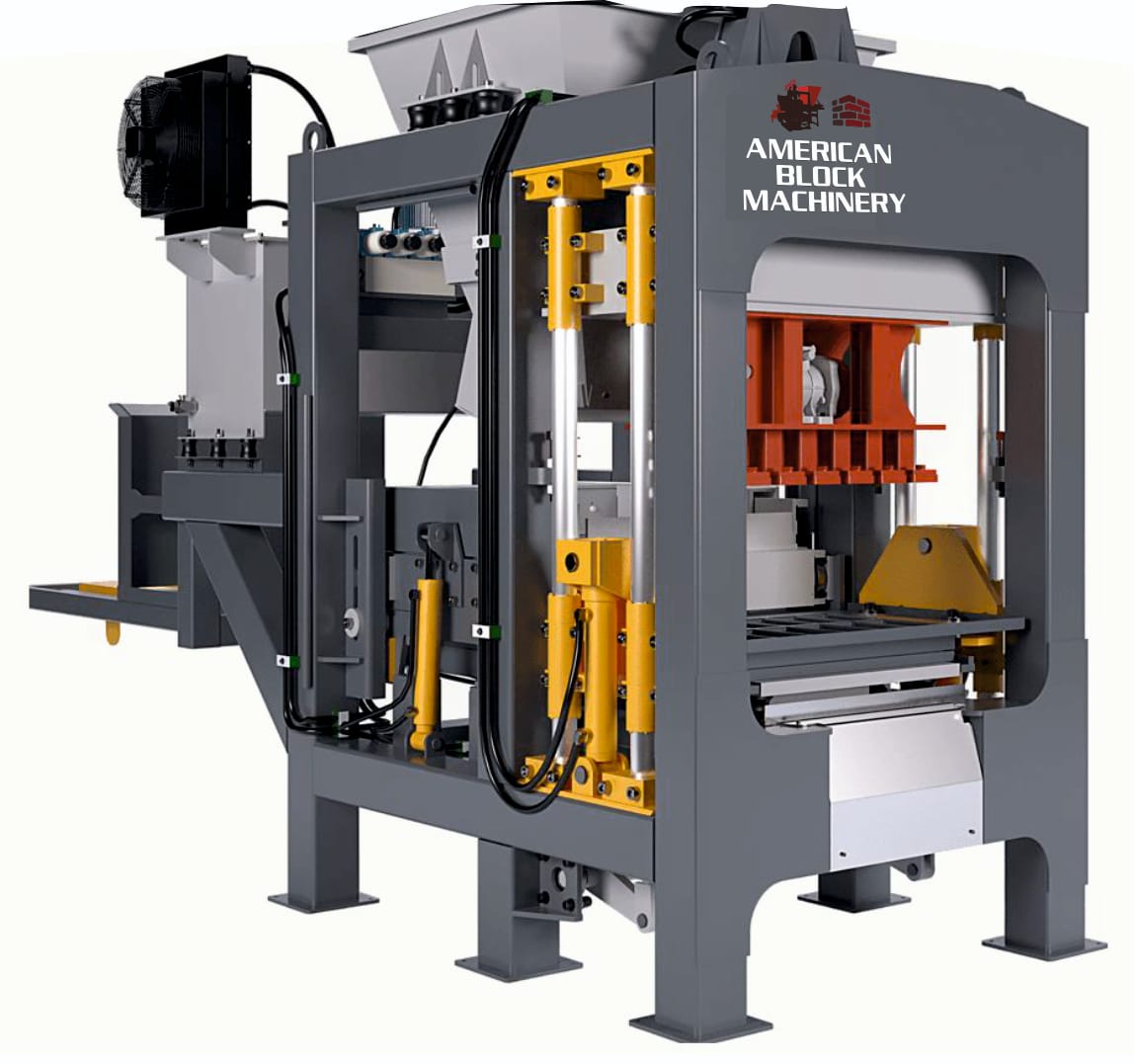

ABM 4000 FULLY AUTOMATIC MACHINE

150,000

Introduction of our second version of FULLY AUTOMATIC MACHINE, specialized mechanics that operate

without the need for manual intervention, performing tasks autonomously through preprogrammed instructions and automated processes. This machine integrates advanced technologies such as sensors, robotics, and artificial intelligence to execute functions efficiently, improve productivity, and

Pallet Size: 35 3/4 x 18 3/4

PRODUCTION WISE

Each Cycle Takes 30-45 seconds.

- 100 x 200 x 400 mold (4″) = 7500 10-12 HR Shift

- 150 x 200 x 400 mold (6″) = 5000 10-12 HR Shift

- 200 x 200 x 400 mold (8″) = 3750 10-12 HR Shift

reduce human error during your block making process. A complete production line – mixing raw materials (like cement, sand, gravel, or aggregates), molding the blocks, curing, and stacking -all controlled by a programmable logic controller (PLC) system.

This automation reduces labor costs and ensures consistent quality. They often feature hydraulic systems for pressing and vibration technology to compact the materials, resulting in strong, uniform blocks.

These machines can produce a variety of products – hollow blocks, solid blocks, interlocking pavers, or even curb stones – depending on the mold used. Production capacity varies widely, from a few thousand to over 3000-6000 blocks per day (24hrs), depending on the model and configuration. Advanced

models might include features like remote monitoring, fault diagnostics, and energy-efficient designs.