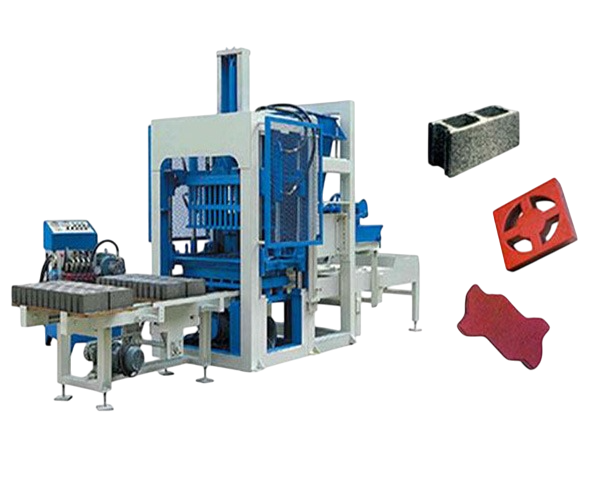

ABM-SHD-754 SEMI-AUTOMATICHYDRAULIC BLOCK MAKING MACHINE

38,500

Pallet Size: 351/2 x 193/4

PRODUCTION WISE

Each Cycle Takes 90 second – 2 minutes (754)

- 100 x 200 x 400 mold (4″) = 7 blocks per cycle

- 150 x 200 x 400 mold (6″) = 5 blocks per cycle

- 200 x 200 x 400 mold (8″) = 4 blocks per cycle

A semi-automated hydraulic machine blends human input with automated processes, using hydraulic power to perform tasks like pressing, cutting, bending, or lifting. These machines rely on pressurized fluid,

typically oil, to transmit force, offering high power density and precision for heavy-duty work. Unlike fully automated systems, they require an operator to handle tasks such as loading materials, initiating cycles, or adjusting settings, while the machine automates repetitive or complex actions.

This is two of best seller and budget friendly semi-automatic hydraulic stationary machines that we currently feature. This machine can utilize both hydraulic and pneumatic systems, depending on the

customer’s preference.

This machine can produce a variety of products-hollow blocks, solid blocks, interlocking pavers, or even curb stones-depending on the mold used. Production capacity varies widely, from a few thousand to over 2100-3500 blocks per day (24hrs), depending on the model and configuration. Advanced models might

include features like suggested that you use a high-capacity mixer of over 500 liters. A workforce of 3 to 5 employees would keep this factory running at full capacity. For example, a semi-automatic hydraulic press

might have an operator place a work piece, but the pressing action-driven by hydraulic cylinders-happens automatically with consistent force.

The upside is efficiency and safety: operators avoid the most strenuous or risky tasks, and the machine ensures repeatability unlike with manual or movable machines. However, they’re often limited to mid-to-high volume production, as human involvement slows things compared to full automation. Maintenance is another factor-hydraulic systems need regular checks for leaks or fluid contamination.